Delta Unisaw (1963) Restoration

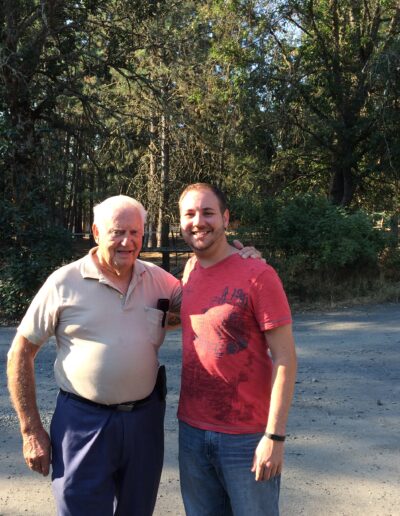

I want to dedicate this post to a truly inspiring man, my grandfather, Walt Dye. For the last several months, without his knowledge, I restored his Delta Unisaw (1963) from the ground up; and here’s the tale of the journey..

Before we get into the details of this post, here are a few things you need to know to understand the meaning behind it:

- Grandpa Walt is 96 years old. He’ll be 97 in July of 2021.

- He was married to my Grandmother, Dorothy for 75 years

- They both lived through the Great Depression

- They graduated high school in 1942

- He arrived in Normandy on June 6th, 1944. He returned home in April of 1945 after losing a leg in Germany (guess I should add – he was a combat medic during WWII).

- They got married in 1946, and had 5 children together

- Grandpa Walt started his woodworking business, ABC Supply & Service in 1958

- Why would anyone name a woodworking business ABC Supply & Service? Because it would be the first listing in the phone book; talk about some old school sales strategies.

- My grandmother passed away peacefully in their home (2020 – and no, not from Covid-19). This was one of the most important things to my Grandfather. He was adamant that she was going to be at the house and not in a hospital as long as he was on this earth. His exact words were “I made a commitment to her that I would take care of her for a long as we both shall live”. While we’ve all heard that statement before, not all people actually live it. There’s a reason they call them the Greatest Generation!

- For all intents and purposes, Grandpa Walt is the toughest man I’ve ever come across.

- Update – It is with a sad heart that I share Grandpa Walt passed away on October 29th 2021, 4 months after I sent him this page; he was 97 years old. He left this world on his own terms, at home.

What could all of that have to do with restoring a Delta Unisaw (1963)? Grandpa Walt bought this Delta Unisaw new in 1963. I’m not sure of his exact age the last time he used it, but he was in his 90’s. So, for over 50 years, this saw was at the center of his shop. This saw will now be at the center of my shop (next to my other table saw), and I hope to continue the legacy my Grandpa started years ago.

Grandpa Walt decided he would like for me to have his woodworking tools. So, in December of 2020 – I flew to Oregon, had a semi-trailer delivered, loaded the trailer with the tools, and had them sent across the U.S. to my shop in Alabama.

Here’s the saw after I unloaded it from the trailer.

I then started to disassemble the saw. Keep in mind this Delta Unisaw hasn’t been apart since 1963. It was in great shape, it just needed some cleaning.

I cleaned the parts using WD-40 and AeroKroil and got them ready for paint. I used an angle grinder with wire wheels to clean off all of the paint from the cabinet. Once all of the paint was removed from the cabinet, I cut a hole in it to plumb in dust collection (I’ll have another post on this later). Taping was a pain in the butt, it took a couple of hours to tape off everything properly.

Then it was time to prime everything. I used Rustoleum Clean Metal Primer in my Fuji Spray Q5 Platinum sprayer along with the 3M PPS 2.0 h/o system.

Appartently my face touched the lip of the cabinet as I was priming the inside.

WARNING!!! Should you get primer on you (or your face in my case), do not under any circumstances do what I did… I didn’t think it would be smart to use Mineral Spirits on my face (especially that close to my eye). So what did my stupid self do; I decided to use a Scotch-Brite Pad – on my face… Dummy!

As my parts were drying, I soaked the table top in Coke so it would penetrate the rust and aid in the cleaning process. They looked at me kind of funny when I went to Publix at 8:30PM and bought 24 2L’s of Coke. I let the tops soak in Coke for about a week before I took them out and sanded them with my Festool ETS 150/5 sander. I started with 120 Grit and worked my way up to 320 Grit. The pictures are during the Coke bath, and after I cleaned up the tops.

Now it’s time to paint the parts. I took the front door plate to Sherwin-Williams and had them paint match the color. I used the Sherwin-Williams All Surface Enamel Oil Base paint, sprayed with my Fuji Spray Q5 Platinum.

Now comes the fun part; assembling the Delta Unisaw.

I assembled the mobile base (more on this later), and then I started the saw assembly on the base. I figured it would be easier to do it that way, rather than build both of them separate and then lift the saw onto the mobile base.

Next I installed the hand wheels, the door, the blade angle gauge, and the switch. While I restored most of the parts to new, I wanted to leave certain pieces original / untouched. I cleaned the dust off of the hand wheels, but I left them with the original paint and scuffs. When I use this saw, I wanted to touch the exact same wheels and switch that my Grandpa used every time he used this saw. I will be adding a magnetic starter switch to the saw later, but it will be wired through the original switch.

Once I had all of the components installed and back in order, it was time to add the finishing touches. I wanted to do something special to honor my Grandpa! I did some searching and found Stencils Online. I sent them my company logo, asked them to create one for my Grandpa’s company, and had them make stencils for me. Then I airbrushed both of our company logos on the cabinet. I used a light blue for my Grandpa’s as that’s his favorite color. I never used an airbrush before this, so it was fun to learn. I think they turned out pretty good!

I was on a roll, getting everything put back together, airbrushing our logos on the cabinet, now it was time for the motor cover. How hard could that be, it’s 4 screws? I screwed the motor cover in place, great! Except, when I went to turn the wheel to raise the blade, it didn’t move. I didn’t even think to measure the new motor before I installed it… I took the 4 screws out and saw that the motor was rubbing on the cover. I didn’t want to replace the cover as it’s the original motor cover (which a lot of these old Unisaw’s don’t have), so I fabricated a spacer to give the motor some extra room. I actually bolted the motor cover on after I installed the last pieces because I was waiting on the paint to dry.

It’s about time to wrap this project up. All I had left was to install my Forrest Woodworker II blade, my Shark Guard over blade dust collector (I used the Delta ARK package which included the riving knife), my extension table and fence, and my JessEm Clear-Cut Table Saw Stock Guides. My other saw in the shop is a SawStop and I like the table and fence it has. So I had my buddy Andy Waites (the store manager at Woodcraft of Birmingham) order me a SawStop table and fence for my Delta Unisaw. I know some of you will say it’s blasphemy, but I really don’t care, it’s in my shop (and I have the originals).

Now it’s time for the final (external) piece. I decided to change out the sliding table as the edge banding on the old one was coming off.

That wraps up the Delta Unisaw restoration project for now. I have a few other modifications I want to make, but I’m extremely happy with the way the saw turned out so far! This has been a fun and rewarding project. I hope Grandpa likes what I did, and I hope he’s proud that his legacy will continue on in my shop. Keep checking back for updates, and feel free to leave comments – especially to show Grandpa Walt some love. If they’re not respectful or constructive, don’t bother as they’ll be deleted.

1 Comment

Submit a Comment

You must be logged in to post a comment.

Corey, you don’t need to delete this, because with proper care, which you are good at, this will self destruct in time. It floors me to think you spents so much time, money and effort, on the heart of my company, the Unisaw. I didn’t get rich with it, but made a good living and it was dependable and I enjoyed the use for many years. I’m glad it has a good home. Some of your comments makes it hard to live up to them ( but I’ll try). You can be sure of one thing Corey, it makes me happy and very proud to call you my Grandson.